Matthew

I build things

A 3rd year engineering student with a passion for everything engineering. Building robots, flying rockets, writing software; as long as I’m making things, I’m happy.

A 3rd year engineering student with a passion for everything engineering. Building robots, flying rockets, writing software; as long as I’m making things, I’m happy.

I'm a 3rd year Mechanical Engineering student at Northeastern University with a passion for robotics and aerospace. I love everything engineering, and I'm happiest when working on interdisciplinary projects and learning new things.

When not in class or building model rockets, I can usually be found crocheting, sailing, or playing Terraforming Mars.

Here are some of the tools and software I’ve had experience using:

I developed and refactored instrument simulation models for the Monarch surgical robot in C++ and Python.

The existing simulation code had limited physics modeling, and much of the instrument control algorithm used on the physical system had to be disabled in simulation. I was responsible for creating physics models based on procedure data logs. By modeling instrument behavior, the same control algorithms could be used in simulation as on the physical system, enabling verification of procedure workflow and increasing unit-test coverage.

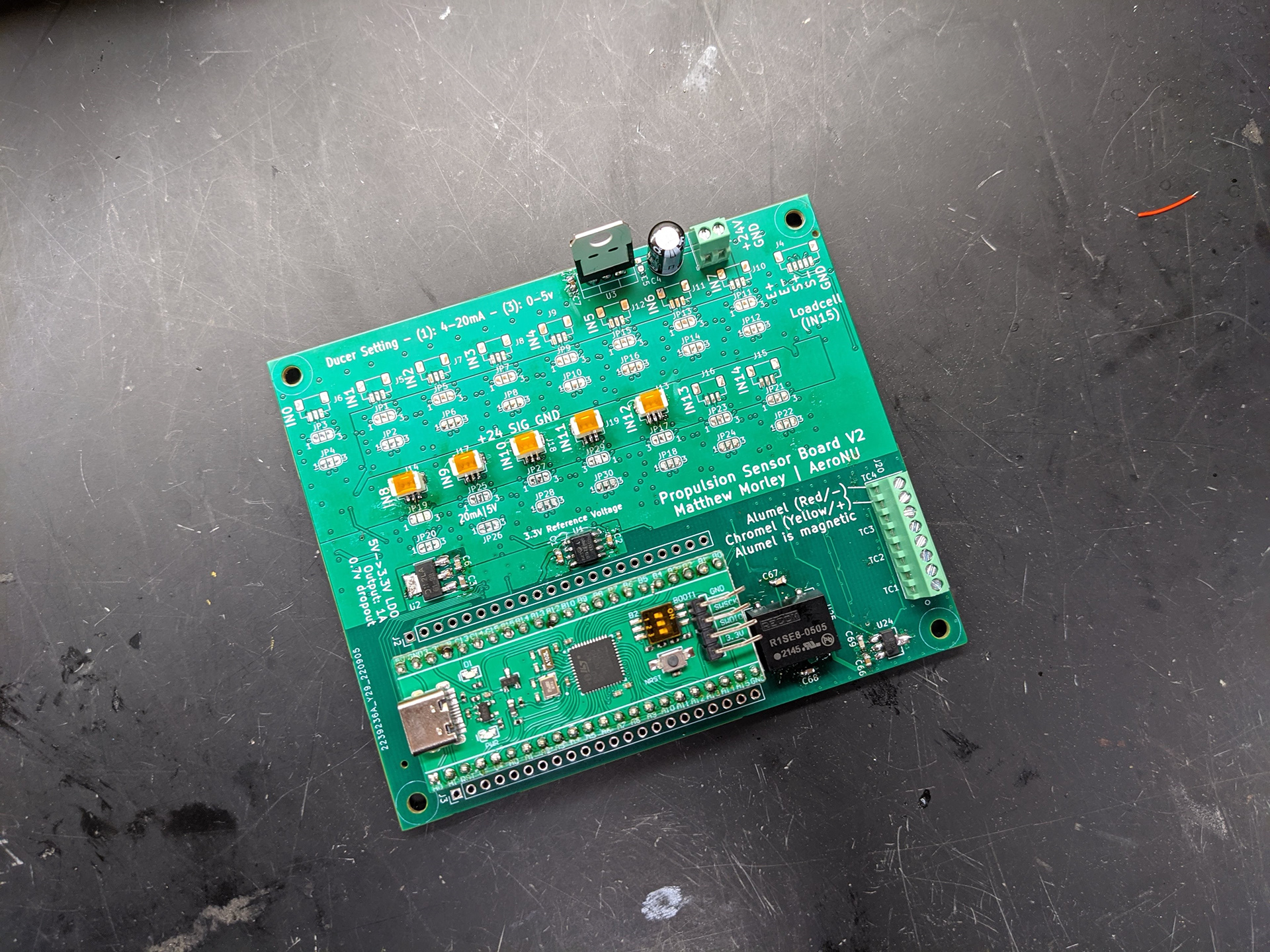

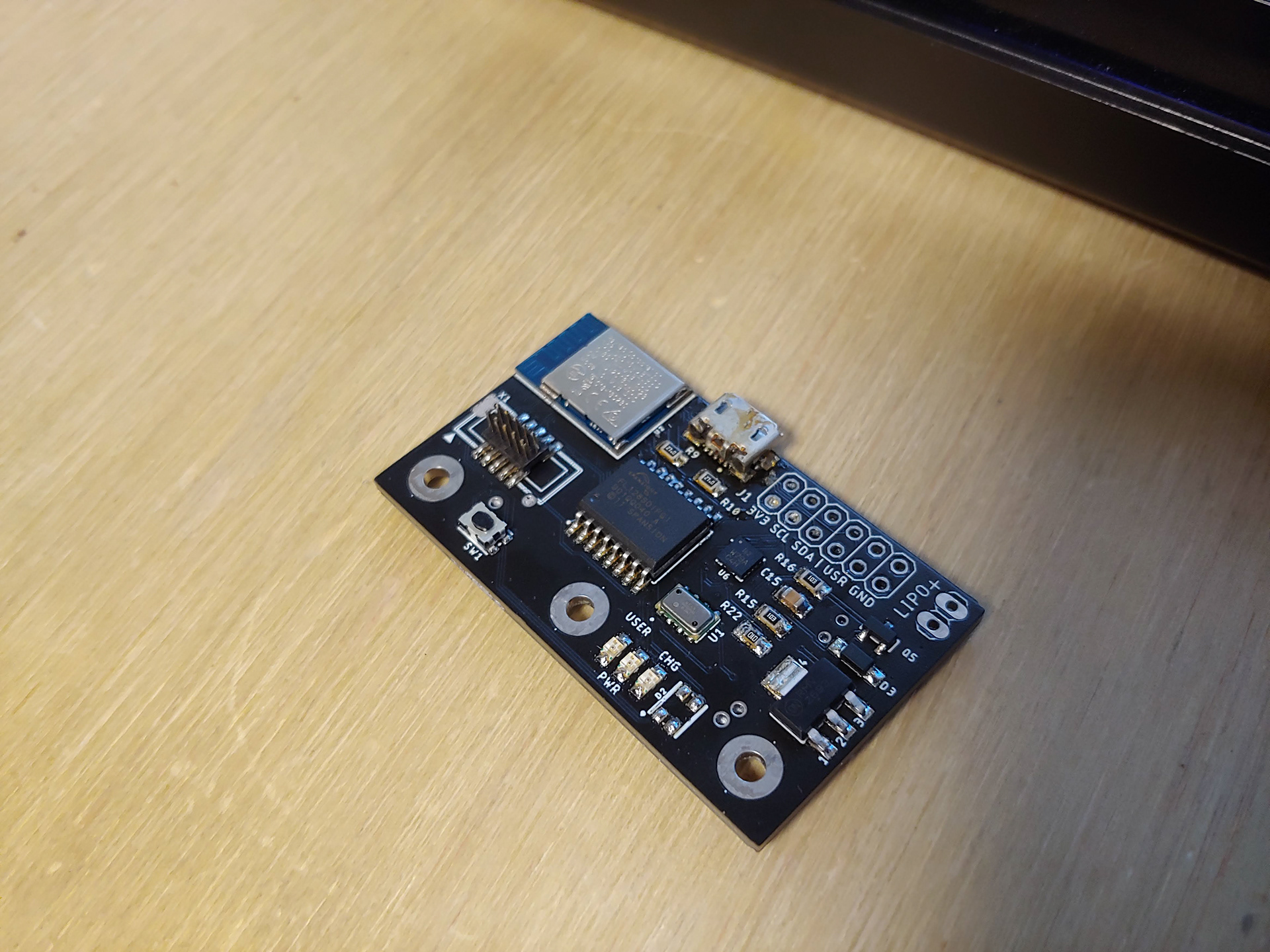

I performed new drone avionics bringup and debugging, designed PCBs, and wrote embedded software. I had the chance to work on a range of hardware and software projects, while supporting flight operations for the fleet of deployed GreenSight drones. My projects included design and assembly of drone avionics PCBs in KiCad, writing embedded software for LiDAR sensor arrays with C++ and ROS, and identifying issues with and reworking existing circuit boards.

I was also responsible for supporting flight operations by remotely managing daily drone flights capturing multispectral imagery at customer locations across the US. I gained my FAA Part 107 remote pilot license and performed test flights to evaluate experimental drone performance in real-world conditions.

My main project was the mechanical design, programming, and deployment of actuator test fixtures for the Ottava surgical robot. The fixtures repeatably measured safety-critical joint performance metrics on the manufacturing line, enabling verification against subsystem specifications.

I designed machined parts and generated drawings with GD&T using SOLIDWORKS and SOLIDWORKS PDM, and interfaced with quick-turn vendors to order machined parts. I also released fixture parts and drawing in Agile PLM.

I used Visual C++ to interface with COTS sensor and motor driver APIs, and created a basic Python GUI to visualize results and post-process test data using TKinter.